Difference between revisions of "Precision Pendulum Assembly: Apparatus description"

m (Ist165696 moved page Precision Pendulum Assembly: Apparatus Description to Precision Pendulum Assembly: Apparatus description: cenas) |

|||

| Line 19: | Line 19: | ||

| − | The support for the fulcrum is made from any robust | + | The support for the fulcrum is made from any robust and hard flat surface as for instance a brass or stainless steel piece with a 12-16mm hole. This surface has an indentation made with a diamond or hard steel blade which holds the pivot in place. With this design, slippage is avoided. |

The fulcrum itself is made as well of stainless steel or brass consisting in a triangular prism with 50mmx9mm with a central 1mm hole in one face crossing the opposite edge. In this hole is soldered an intravenous needle where the pendulum string is glued or soldered. | The fulcrum itself is made as well of stainless steel or brass consisting in a triangular prism with 50mmx9mm with a central 1mm hole in one face crossing the opposite edge. In this hole is soldered an intravenous needle where the pendulum string is glued or soldered. | ||

Revision as of 12:16, 26 December 2019

Apparatus description

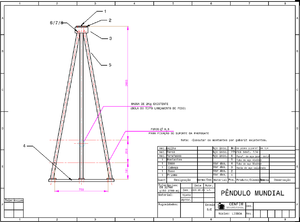

The pendulum apparatus is composed of three components: the supporting structure for the pendulum fulcrum, the launcher of the pendulum mass and the controller electronics.

The basic support can be a wall or a robust metallic structure like the one presented here. The choice for the mass was a training steel weight from the official shot put with 2kg. This weight has the advantage of having a drilled hole for holding an M4 screw and can be found in any good sports shop. This screw can be made of a threaded brass rod with 10mm length. A small 1mm hole is drilled on the rod were the pendulum string is soldered using current soldering thin-plumb(or any silver-thin alloy). The string used is from 0.4mm remanium wire that can be bought in any dentistry retailer. The other end is soldered to the same brass rod with a length of 50mm, using the same technique (1mm hole and soldering).

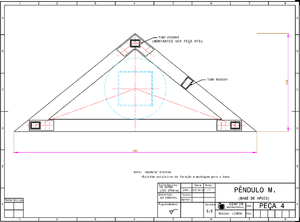

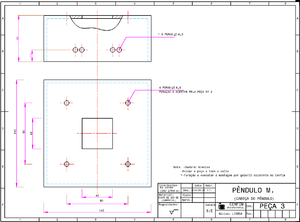

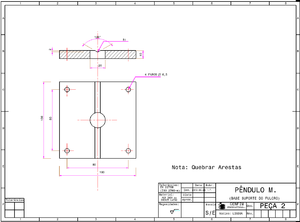

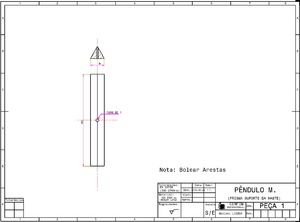

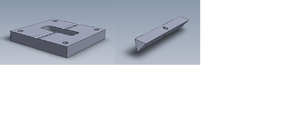

The following drawings document the construction of the metallic pendulum's sections.

The support for the fulcrum is made from any robust and hard flat surface as for instance a brass or stainless steel piece with a 12-16mm hole. This surface has an indentation made with a diamond or hard steel blade which holds the pivot in place. With this design, slippage is avoided.

The fulcrum itself is made as well of stainless steel or brass consisting in a triangular prism with 50mmx9mm with a central 1mm hole in one face crossing the opposite edge. In this hole is soldered an intravenous needle where the pendulum string is glued or soldered.